The foundation of the FBS blocks is one of the most durable and reliable types of supporting structures. The process of creating this foundation can be considered on a specific example.

Example. The land plot, which is located on clay soil, has not been processed for a long time. In this case, the advantage is a sufficiently large depth of moisture (about 30 meters). A significant amount of reinforcement, fifty concrete blocks, as well as other necessary building materials were purchased. The elements of the supporting structure, in order to save, were acquired used, but in good condition.

For foundation calculation you can use foundation calculator .

Stage 1. Clearing the area. If there is not very much time for construction, then it is better to immediately entrust the construction of the foundation from FBS blocks to specialists. You can hire people to perform all types of work, or you can be charged with performing various small ones, for example, to clean the old structures from the supporting structures or to clean the garbage. An excavator was hired to dig a foundation pit. The working change of special equipment cost 330-350 US dollars. The depth of the pit under the tape is about 30 cm. To create a "pillow", sand is poured into a trench with a layer of 10 cm. Online calculator for calculating the weight of reinforcement for strip foundations.

It took a little more than one week to clear the land, process the concrete blocks and create the trench. Specialists with sufficiently high qualifications charge an average of $ 35 per working day. Total, hiring of workers and special equipment cost about $ 700.

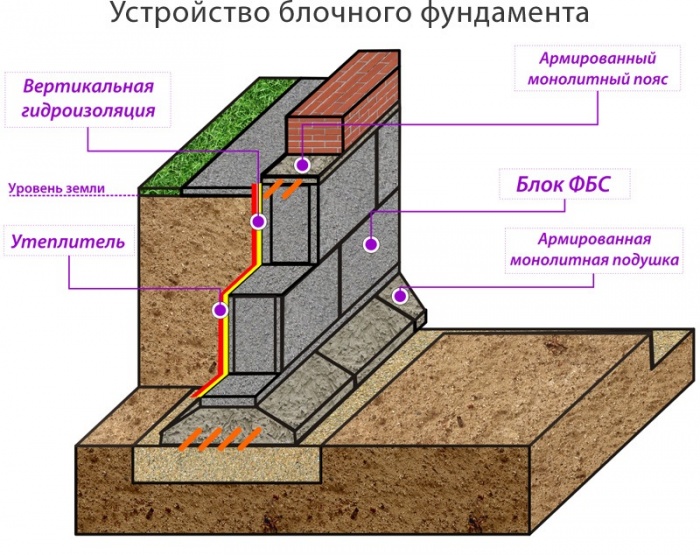

Stage 2 Construction of formwork. If you have certain skills, you can make the formwork yourself. According to the building construction project, its parameters are 6x9 m. When reinforcing the foundation from blocks , old rods are used (saving on the acquisition of new ones). Two products are installed on each side. Sand, gravel and ten bags of cement were additionally purchased to create the foundation. The cost of sand and gravel was 70 US dollars. Cement cost $ 110, but shipping services cost $ 200.

In order to knead the solution was acquired concrete mixer, which is designed for 160 liters. Its price was 340 US dollars. On the tape for the foundation for greater reliability was laid gidrostekloizol.

After the concrete solution has been prepared, the mixture is poured into the tape and left to dry completely. Thanks to this stage, the foundations of the FBS blocks are called this way.

All work is performed in accordance with the detailed plan developed. The overlap of the joints refers to very important stages. Alignment is performed using pre-prepared joints.

For foundation construction and the correct installation of blocks FBS, you must rent a crane. One work shift costs about 230-240 dollars. In addition to these, the crane driver can help with some other work. Other workers closely monitor how well the brickwork is being made and perform actions with the mortar. The final part of this phase of construction work is to seal the remaining joints and holes.

Stage 3 Hydro and thermal insulation. To the foundation of the blocks served as long as possible, you should worry about high-quality waterproofing. In this example, to create a hydroprotective layer, seven rolls of glass hydride were used. Forty liters of resin and special mastic were also used. For work on waterproofing was used gas burner with a hose.

All wall structures were carefully and carefully treated with mastic. A waterproofing material was attached over it. In the areas between the tape and the cement blocks, a hydroprotection film is tucked up.

On the implementation of these works took about two days. After creating a hydroprotective layer, the joints were tested and defects were eliminated. To preserve heat, a layer of foam is laid over the waterproofing.

Then a drainage pipe is installed under a certain slope. At the same time, it wraps itself in geotextiles. This is necessary to protect it from the effects of various negative factors.

The top layer will be a layer of gravel with some sand added.

4 stage. Installation of floor slabs. Before installing the slabs, the specialists level the upper part of the supporting structure. In our case, this was done using formwork. The boards were connected with special threaded rods. Inside the frame is set of reinforcement, which is then poured with cement. The organization from which the slabs were purchased independently delivered them to the construction site. At this stage, crane services are also required for the installation of floor slabs.

Conclusion About 5,000 USD was spent on the resulting construction (including all the necessary materials, rental of special equipment and specialist services). It may seem to some that this is too large a sum, but with the proper laying of the foundation of the blocks, you can be sure that the building will be durable and strong.